Folk Pottery of Alabama

Salt Glaze

Up until the early twentieth century, hundreds of folk potters worked throughout the state of Alabama. Before the age of electrification, their wares were needed for the basics of everyday living, including the preservation, preparation, and serving of food. Families in need of a crock, a churn, a chamber pot, or a storage jar obtained it from their nearest potter or from a merchant who bought from regional potters. Although most of the items produced by these potters were utilitarian in nature, such as churns, chamber pots, and pitchers, some were clearly artistic creations, including face jugs and other anthropomorphic vessels. Small pottery shops perpetuated regional and family folk pottery traditions throughout Alabama, and although many potters succumbed to changing technology and competition, a few of the state’s historic potteries remain.

Salt Glaze

Up until the early twentieth century, hundreds of folk potters worked throughout the state of Alabama. Before the age of electrification, their wares were needed for the basics of everyday living, including the preservation, preparation, and serving of food. Families in need of a crock, a churn, a chamber pot, or a storage jar obtained it from their nearest potter or from a merchant who bought from regional potters. Although most of the items produced by these potters were utilitarian in nature, such as churns, chamber pots, and pitchers, some were clearly artistic creations, including face jugs and other anthropomorphic vessels. Small pottery shops perpetuated regional and family folk pottery traditions throughout Alabama, and although many potters succumbed to changing technology and competition, a few of the state’s historic potteries remain.

Early American colonists brought European pottery traditions to America and introduced the basic technology, including the use of the potter’s wheel, large kilns and glazes. The typical southern pottery-making family would move from South Carolina to Georgia, then to Alabama or Mississippi. From there, many continued west to Texas, but enough of these families remained in Alabama to create strong regional pottery traditions. Eventually, these areas developed into regional pottery manufacturing centers such as those in DeKalb County on the southern edge of Sand Mountain, Rock Mills in Randolph County, in Perry County,and at Oak Level in Cleburne County. Another characteristic of these regional pottery traditions was their dynastic nature. The sons of potters would often marry the daughters of neighboring potters, thus solidifying the family’s craft tradition for many generations.

Many of these pottery centers became known locally as “jugtowns.” For example, Gardendale, which is just north of Birmingham, appeared on maps as “Jugtown” until the early twentieth century. A community outside of Sterrett was also referred to as “Jugtown,” and Redland in Elmore County was once called “Pottersville.” Today, there is a Jug Factory Road in both Tuscaloosa and Elmore County. Potter’s Bend, a modern subdivision in Baldwin County, also pays homage to its ceramic heritage.

Early potters located near clays suitable for making pots, which in Alabama occurred in all of the major physiographic sections. Clays in some regions, such as the Eastern Shore of Mobile Bay, much of east-central Alabama, the mountains of northeast Alabama, the Tuscaloosa area, and the northwest counties of Marion and Lamar, attracted potters who specialized in a type of pottery known as stoneware. This pottery type requires clay that is plastic enough to shape into a vessel and that can withstand temperatures of 2,500°F for firing.

Alkaline Glaze

The manufacture of stoneware quickly became a viable industry in many Alabama communities. The characteristics of Alabama folk pottery reflect the two main American stoneware traditions: salt glazed and alkaline glazed. Salt glazing, the most common type of glaze for early stoneware, was brought to Alabama by immigrants from north of the Tennessee River, especially those from the Ohio Valley, and from Europe. The tradition first appears in the Mobile area and northwest Alabama well before the Civil War. Salt glazing is accomplished by throwing salt into a hot kiln after the pots have been loaded into it. The salt vaporizes, and the resulting gasses create a glass coating on the pottery, giving it a matte or “orange peel” texture. Many potters also coated the interior of the vessels with another glaze because the salt vapors cannot reach the inside of narrow-mouthed vessels.

Alkaline Glaze

The manufacture of stoneware quickly became a viable industry in many Alabama communities. The characteristics of Alabama folk pottery reflect the two main American stoneware traditions: salt glazed and alkaline glazed. Salt glazing, the most common type of glaze for early stoneware, was brought to Alabama by immigrants from north of the Tennessee River, especially those from the Ohio Valley, and from Europe. The tradition first appears in the Mobile area and northwest Alabama well before the Civil War. Salt glazing is accomplished by throwing salt into a hot kiln after the pots have been loaded into it. The salt vaporizes, and the resulting gasses create a glass coating on the pottery, giving it a matte or “orange peel” texture. Many potters also coated the interior of the vessels with another glaze because the salt vapors cannot reach the inside of narrow-mouthed vessels.

Groundhog Kiln

Potters who emigrated to Alabama from the Edgefield District of South Carolina brought with them a distinctly southern style of stoneware pottery known as alkaline glazing for its use of lime or wood ashes. Families such as the Leopards, Presleys, and Rushtons established potteries in the state. The items they produced were coated with a glaze made from either clay mixed with wood ashes or lime mixed with clay or clay and sand. This type of glaze produced a glassy green-to-brown surface on the stoneware. These potters also introduced a type of rectangular kiln known as a “groundhog” kiln, which was used early on by potters who preferred alkaline glazes and was later adopted by other potters as well.

Groundhog Kiln

Potters who emigrated to Alabama from the Edgefield District of South Carolina brought with them a distinctly southern style of stoneware pottery known as alkaline glazing for its use of lime or wood ashes. Families such as the Leopards, Presleys, and Rushtons established potteries in the state. The items they produced were coated with a glaze made from either clay mixed with wood ashes or lime mixed with clay or clay and sand. This type of glaze produced a glassy green-to-brown surface on the stoneware. These potters also introduced a type of rectangular kiln known as a “groundhog” kiln, which was used early on by potters who preferred alkaline glazes and was later adopted by other potters as well.

During the late nineteenth century, new types of pottery glazes were introduced to Alabama as the railroad system expanded. Glazes such as the brown Albany Slip and white feldspar glaze, also known as Bristol Glaze, largely replaced the salt and alkaline glazes. New immigrants from Europe and northern states brought additional pottery traditions to Alabama and further changed local traditions.

Changing technology and economic factors led to a sharp decline in folk potteries after World War II. Rail lines brought cheaply produced stoneware from northern factories, and northern potters opened new businesses in Alabama that competed with local shops. In addition, developments in food preservation technology made some of the local potter’s best-selling items, such as churns, jars, and jugs, obsolete.

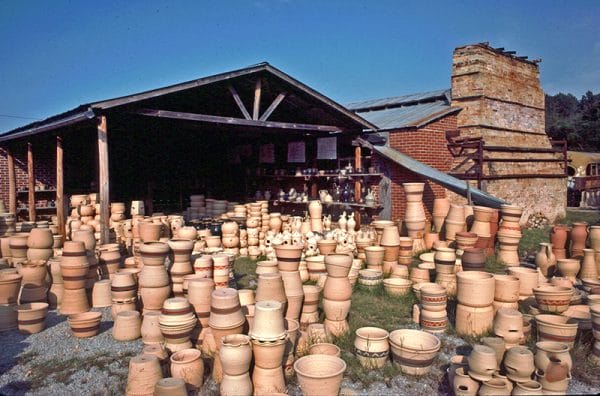

Miller’s Pottery

During the late twentieth century, the few remaining Alabama folk potters received interest from a mostly urban collecting market focused on art pieces that reflected a folk heritage. This development coincided with several exhibitions about Alabama folk pottery and a documentary film about Hamilton potter Jerry Brown and further changed the repertoire and marketing for Alabama’s remaining folk potters. Brown had initially priced his pottery by the gallon, a traditional practice, but quickly began pricing by form, with face jugs garnering the highest prices. The Browns and fellow Alabama potters the Millers, who have a shop in Brent, Bibb County, also began experimenting with glaze combinations and unusual forms in response to or in anticipation of market desires. Festival and internet sales became important for both families. Brown, the Millers, and a handful of potters continue Alabama’s long tradition of folk pottery production.

Miller’s Pottery

During the late twentieth century, the few remaining Alabama folk potters received interest from a mostly urban collecting market focused on art pieces that reflected a folk heritage. This development coincided with several exhibitions about Alabama folk pottery and a documentary film about Hamilton potter Jerry Brown and further changed the repertoire and marketing for Alabama’s remaining folk potters. Brown had initially priced his pottery by the gallon, a traditional practice, but quickly began pricing by form, with face jugs garnering the highest prices. The Browns and fellow Alabama potters the Millers, who have a shop in Brent, Bibb County, also began experimenting with glaze combinations and unusual forms in response to or in anticipation of market desires. Festival and internet sales became important for both families. Brown, the Millers, and a handful of potters continue Alabama’s long tradition of folk pottery production.

Additional Resources

Brackner, Joey. “A Heritage in Clay: The Lineage of Robert Ussery,” Alabama Heritage 82 (Fall 2006): 16-23.

———. Alabama Folk Pottery. Tuscaloosa: University of Alabama Press, 2006.

———. “Made of Alabama: Alabama Folk Pottery and Its Creators.” In E. Bryding Adams, ed., Made in Alabama: A State Legacy. Birmingham, Ala.: Birmingham Museum of Art, 1995.

———. “Traditional Pottery of Mobile Bay.” Alabama Heritage 7 (Winter 1988): 30-41.

Brown, Jerry. Of Mules and Mud: The Story of Alabama Folk Potter Jerry Brown. Tuscaloosa: University of Alabama Press, 2022.

Shores, Max. Miller’s Pottery: Turning for Generations. Directed by Max Shores. Tuscaloosa, Ala.: Center for Public Television and Radio, 1997.