Dairy Industry in Alabama

Dairies and milk production in Alabama are closely aligned with the history of the state. Dairying initially started on small family farms and as side businesses, but dairy operations today are multimillion-dollar businesses even though most continue to be family owned and operated. Although commercial dairies in Alabama have been on the decline in recent years, similar to elsewhere in the nation, the industry continues to make large contributions to the state’s economy. Since the 1970s, most production has been for fluid milk consumption. Niche markets, such as cheese and organic milk products, are providing new outlets for Alabama’s dairy farmers in the future. Alabama’s top dairy-producing counties are Houston, Cullman, and Fayette.

Early Dairy Enterprises

During the territorial period, dairying existed primarily in the form of family milk cows kept to supply milk and butter for the immediate household. Surplus milk and milk products were sold to

Marion County Dairy Farmers 1927

neighbors and eating establishments. By the late nineteenth century, several specialized dairy farms were providing dairy products to the larger cities, although most milk was produced by farms that kept family milk cows or milked a few cows, often by hand, as a sideline. The first commercial creamery (a plant that purchases milk or cream and processes and delivers dairy products) was opened in Fairhope in 1908, followed by one in Auburn in 1914, and others soon afterward in Decatur, Selma, and elsewhere. Into the early 1940s, creameries produced butter, cheese, and dried milk products and processed fluid milk for consumption. Dairying continued to increase, and milk cow numbers peaked at 415,000 in 1944. Most of the individual operations remained small, with between three and 12 milk-producing cows; a farm with 30 cows was considered a large operation even in the early 1950s. Dairy owners worked closely with extension agents, veterinarians, and industry personnel to develop improved feeding, breeding, and management techniques for their herds, improved pastures and crops, and invested in new technologies, such as milking machines, cooling facilities, and feed lots. Most cows kept as a sideline business often did not receive such attention, and subsequently the returns to owners were small amounts of milk, with an average production of less than 3,000 pounds per year. By the 1960s, dairies were specialized operations, and the sideline milking business and family milking cow had essentially disappeared.

Marion County Dairy Farmers 1927

neighbors and eating establishments. By the late nineteenth century, several specialized dairy farms were providing dairy products to the larger cities, although most milk was produced by farms that kept family milk cows or milked a few cows, often by hand, as a sideline. The first commercial creamery (a plant that purchases milk or cream and processes and delivers dairy products) was opened in Fairhope in 1908, followed by one in Auburn in 1914, and others soon afterward in Decatur, Selma, and elsewhere. Into the early 1940s, creameries produced butter, cheese, and dried milk products and processed fluid milk for consumption. Dairying continued to increase, and milk cow numbers peaked at 415,000 in 1944. Most of the individual operations remained small, with between three and 12 milk-producing cows; a farm with 30 cows was considered a large operation even in the early 1950s. Dairy owners worked closely with extension agents, veterinarians, and industry personnel to develop improved feeding, breeding, and management techniques for their herds, improved pastures and crops, and invested in new technologies, such as milking machines, cooling facilities, and feed lots. Most cows kept as a sideline business often did not receive such attention, and subsequently the returns to owners were small amounts of milk, with an average production of less than 3,000 pounds per year. By the 1960s, dairies were specialized operations, and the sideline milking business and family milking cow had essentially disappeared.

Dairy Cattle Breeds

The earliest record of dairy cattle in Alabama is 1836. Because there was little emphasis on maintaining pure bloodlines, most of these early cattle, called scrub cattle, were of nondescript breeding. As early as 1836, progressive farmers began purchasing purebred dairy cattle and also bred the scrub cows selectively to purebred dairy bulls to improve milk production. This trend increased slowly, but by the 1940s most milk cows had some genetic background of the

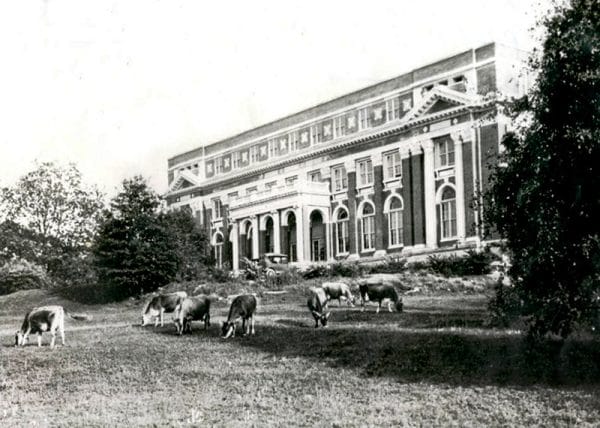

Dairy Cattle Near Comer Hall

major dairy breeds, specifically Ayrshire, Brown Swiss, Guernsey, Jersey, Holstein, and Milking Shorthorn cattle, all of which were popular dairy breeds in different areas of Europe. Many of the cows into the 1950s, however, were at least part Jersey, a small, fawn-colored breed that remains valued for its high-fat milk.

Dairy Cattle Near Comer Hall

major dairy breeds, specifically Ayrshire, Brown Swiss, Guernsey, Jersey, Holstein, and Milking Shorthorn cattle, all of which were popular dairy breeds in different areas of Europe. Many of the cows into the 1950s, however, were at least part Jersey, a small, fawn-colored breed that remains valued for its high-fat milk.

By the early 1960s, Jersey cattle had a doubtful future because of low milk production and concerns about fat in the human diet. Their future began to look brighter, however, when some dairy farmers in Alabama and elsewhere improved milk production and efficiency in the breed. The increased demand for cheese during the last three decades has also brought Jerseys back into favor because of the high protein content of the milk. Two Alabama Jersey cows from the Rocky Hill Jersey Farm in Fort Payne, DeKalb County, especially influenced the breed when they were named as National Milk Champions. The most noted of the two, Rocky Hill cow Favorite Deb set a record of 35,881 pounds of milk in 1979, an average of more than 98 pounds per day, a feat that stood for many years. Many of her offspring continue to be used in breeding programs. Cedarcrest Farms, an internationally known Jersey farm in Faunsdale, Marengo County, has had a major impact on improving the breed around the world. This farm developed the Milestone Generator bull in the 1970s, which is listed as one of three Jersey sires that turned the breed around in production and physical traits (ability to thrive). In 1981, Cedarcrest received the National Dairy Shrine’s prestigious Distinguished Dairy Cattle Breeder Award, a yearly honor for those making an impact on improving dairy cattle breeds.

Holstein Cows

In the 1970s, Holsteins, which were few in number in the early twentieth century, became the dominant breed in Alabama because of their high milk production. A few Holstein breeders existed in Selma and near Birmingham in the early twentieth century, but Holsteins were few in number until the 1950s, when dairy producers began purchasing them from out of state to increase their production, a noted characteristic of Holsteins around the world. Some of the increase in Holstein herds was brought about by cross-breeding Jersey cows with Holstein bulls until the herds were essentially purebred Holsteins. Currently, 85 to 90 percent of Alabama dairy cows are Holsteins or Holstein crosses, as is true of most dairy farms in the nation. Alabama Holstein herds produce an average of 18,000 pounds of milk per year, with many herds producing in excess of 20,000 pounds. To achieve such herd production, many individual cows may produce in excess of 30,000 pounds of milk per year, often up to 120 to 150 pounds (14 to 17 gallons) of milk per day at peak lactation. The other dairy cows are generally Jerseys, with a few cows of other breeds found on a small number of farms. In recent years, there has been some interest in crossbreeding, especially of Jerseys and Holsteins, to gain the best of both breeds. Jerseys have fewer calving difficulties and better heat tolerance, and Holsteins have higher milk production.

Holstein Cows

In the 1970s, Holsteins, which were few in number in the early twentieth century, became the dominant breed in Alabama because of their high milk production. A few Holstein breeders existed in Selma and near Birmingham in the early twentieth century, but Holsteins were few in number until the 1950s, when dairy producers began purchasing them from out of state to increase their production, a noted characteristic of Holsteins around the world. Some of the increase in Holstein herds was brought about by cross-breeding Jersey cows with Holstein bulls until the herds were essentially purebred Holsteins. Currently, 85 to 90 percent of Alabama dairy cows are Holsteins or Holstein crosses, as is true of most dairy farms in the nation. Alabama Holstein herds produce an average of 18,000 pounds of milk per year, with many herds producing in excess of 20,000 pounds. To achieve such herd production, many individual cows may produce in excess of 30,000 pounds of milk per year, often up to 120 to 150 pounds (14 to 17 gallons) of milk per day at peak lactation. The other dairy cows are generally Jerseys, with a few cows of other breeds found on a small number of farms. In recent years, there has been some interest in crossbreeding, especially of Jerseys and Holsteins, to gain the best of both breeds. Jerseys have fewer calving difficulties and better heat tolerance, and Holsteins have higher milk production.

The Modern Dairy Industry

The cost of producing milk rapidly increased after the early 1950s due to rising input costs following WWII, and most low-producing, poorly managed farms exited the industry as a result of poor returns and the attraction of increased off farm jobs. By the late 1970s, family milk cows and cows kept as sideline businesses had disappeared. The remaining farms are very specialized dairy operations that average 190 milking cows and more than 200 head of young female replacement animals, called heifers. Several Alabama dairy farmers keep more than 600 cows, and a few have more than 1,000 cows and a similar number of heifers. Alabama dairies are generally privately owned businesses, with some held by individuals but many more as family partnerships or family corporations. Current cow and replacement animal values often exceed $3,000 per head. The cost of animals, coupled with barn, equipment, and facilities, results in operating costs that normally add up to an investment of many

Cedarcrest Farms

millions of dollars. Dairy farms are typically managed by the owner or owners and employ between two and 15 people, all of whom work long hours. Most Alabama dairies also produce much of their own forage (hay, silage, and pasture), and a few grow grain crops, thus increasing investment and labor requirements.

Cedarcrest Farms

millions of dollars. Dairy farms are typically managed by the owner or owners and employ between two and 15 people, all of whom work long hours. Most Alabama dairies also produce much of their own forage (hay, silage, and pasture), and a few grow grain crops, thus increasing investment and labor requirements.

Cows today are milked in a “milking parlor” designed for milking efficiency, sanitary conditions, and cow and worker comfort. Proper milking requires skill, and poor techniques can decrease production and increase udder injury. Cows are normally milked twice a day, but some cows are milked three times to increase production, improve animal health, and reduce overhead costs. The milk is never touched by human hands. Milkers clean and sanitize the cow’s teats and attach machines that channel the milk directly into a stainless steel line that in turn delivers the milk to a large refrigerated bulk milk tank. There, the milk is cooled within two hours to around 40° F (~4° C) and kept until a special tanker truck delivers it to a processing plant. Milk often reaches the grocery shelf within 24 to 48 hours of leaving the cow.

Milking parlors in Alabama are generally located within or near free-stall barns, where dairy cows live while they are lactating. These barns provide shade and misting systems to shield the cows from Alabama’s typically warm climate and allow the cows to move from their individual free (open) stalls, padded with foam or water mattresses, to nearby feed and water. Manure (animal waste) is deposited in a litter alley, which is flushed twice or more per day into a specialized holding lagoon built, maintained, and emptied according to the specifications of the Alabama Department of Environmental Management. Some barns provide access to pastures, but the cows typically prefer the cool environment of the barns.

The modern dairy cow’s diet in Alabama is carefully designed. Dairy producers work with nutrition consultants and researchers to formulate the best diets for cows. The base of most feeds is soft, fine stemmed alfalfa or grass hay and corn silage (a high-energy “pickled” forage derived from the whole corn plant) along with other grain-type feeds to meet optimum levels of protein, energy, fiber, minerals, and vitamins. A lactating cow may eat between 45 and 60 pounds of corn silage as well as another 40 or 50 pounds of a mixture of alfalfa hay, ground corn, whole cottonseed, wet brewers grain, soybean meal, and fish meal a day. The dairy manager works carefully to ensure that rations are properly stored, balanced, and delivered at the correct times. Pastures continue to be an important and economical source of forage for most dairy operations, but they are most often reserved for nonlactating cows and heifers. Although still small, a growing number of Alabama dairy operations use pasture more extensively and supplement cows’ diets with grain fed in the parlor or offered to the cows in bunks near the pasture. Shade structures help alleviate heat stress for animals on pasture.

Breeding and Milk Production

Typical dairy cows calve approximately every 13.7 months, lactate for 11.5 months, and then are turned dry (nonlactating) for two months before calving again. Calves may remain with their mothers to nurse for the first few hours after birth so that they can receive the cow’s first milk, called colostrum, which transfers important infection-fighting antibodies to them. They are then moved to individual calf “hutches” (small portable buildings) and fed milk and specialized feed. All heifers are kept for replacements,

Milking Machine

and male calves are sold within a few weeks to farmers to be raised as beef cattle. Farmers who specialize in dairy breeding stock keep some of the male calves. When heifers reach two years of age, they enter the breeding program. Most calves produced today are the result of artificial insemination (AI), which is the process of impregnating a cow through mechanical means. This procedure was controversial when introduced in the late 1940s, but it has revolutionized the industry by allowing producers access to the very best genetics at low cost without having to keep a very dangerous and genetically unproven bull on the farm. About 85 percent of all Alabama dairy cows are now bred via AI.

Milking Machine

and male calves are sold within a few weeks to farmers to be raised as beef cattle. Farmers who specialize in dairy breeding stock keep some of the male calves. When heifers reach two years of age, they enter the breeding program. Most calves produced today are the result of artificial insemination (AI), which is the process of impregnating a cow through mechanical means. This procedure was controversial when introduced in the late 1940s, but it has revolutionized the industry by allowing producers access to the very best genetics at low cost without having to keep a very dangerous and genetically unproven bull on the farm. About 85 percent of all Alabama dairy cows are now bred via AI.

Milk Safety and Animal Health

Alabama dairy producers work closely with animal health scientists and state health agencies to maintain the health of their animals and milk quality. The dairy industry originally had little oversight from the Alabama Public Health Department (PHD), but in 1912 the Cloverdale Dairy in Shades Valley became the first Alabama dairy to meet PHD quality standards for raw milk. This program raised awareness of milk safety, but even certified raw milk may contain pathogens harmful to humans. By 1918, pasteurization, a process of heating milk to specific temperatures to kill pathogens, was implemented by most processing plants in the state. Farm inspections also increased at this time because the government wanted to assure the safety of milk products supplied to the military during World War I.

Into the early twentieth century tick fever caused large losses in cattle, but the disease was brought under control early in the century by state programs that eradicated the parasite. Brucellosis and tuberculosis, diseases that cause poor performance in dairy cattle and can be passed on to humans, were special problems through the 1940s. A number of state and federal programs implemented from about the 1930s, such as milk testing and cattle vaccination programs, have essentially

Dairy Calf in Hutch

eliminated these and other harmful diseases. Producers and state regulations continue to maintain rigorous vaccination and preventative health programs to keep all animals healthy and to keep dairy products safe for consumption. The cooled milk collected at the farm is delivered to plants in the state for processing, packaging, and delivery to grocers. All dairies, processing plants, transportation vehicles, and other aspects of the dairy industry must be licensed and inspected to ensure that they meet the rigorous sanitation, cooling, and health standards of the PHD. Raw milk cannot be sold in Alabama.

Dairy Calf in Hutch

eliminated these and other harmful diseases. Producers and state regulations continue to maintain rigorous vaccination and preventative health programs to keep all animals healthy and to keep dairy products safe for consumption. The cooled milk collected at the farm is delivered to plants in the state for processing, packaging, and delivery to grocers. All dairies, processing plants, transportation vehicles, and other aspects of the dairy industry must be licensed and inspected to ensure that they meet the rigorous sanitation, cooling, and health standards of the PHD. Raw milk cannot be sold in Alabama.

The Dairy Industry and Support Organizations

Many state agencies and institutions have been instrumental in developing the state’s dairy industry. The Agricultural and Mechanical College of Alabama (now Auburn University) established a research herd in 1888, and nearby Tuskegee Institute built a state-of-the-art dairy facility in 1918. These institutions, as well as Alabama A&M University, conducted research, provided bulls to improve herds, developed AI bull studs in later years, and conducted specialized extension programs. Other schools, such as the University of Montevallo and Oakwood College, and several penal institutions kept dairy operations in their early years to furnish milk for the students and inmates. Many of these institutions ended their dairy-related activities as costs of facilities and labor increased and farmland declined. Auburn University closed its last dairy in June 2014. The colleges of veterinary medicine at Auburn and Tuskegee in cooperation with the Extension Service have been instrumental in improving cow health in Alabama since the early twentieth century.

Alabama’s dairy farmers have become adept at developing marketing co-ops, lobbying, answering consumer concerns, and supporting research to improve products and markets. The Dairy Committee of the Alabama Farmers Federation is the major organization that works on legislation that affects the Alabama dairy industry, although some farmers also work independently on farm issues. Since the 1970s, dairy farmers have contributed to marketing and educational efforts by American Dairy Association of Alabama, in partnership with the Southeast United Dairy Industry Association, to promote dairy products and to provide nutritional information to consumers. In 2001, the association created a mobile milking parlor with a live cow that travels to schools, youth events, and fairs to demonstrate the milking process to the public and to promote the dairy industry and its products. Scores of veterinarians, nutritionists, waste-management consultants, engineers, equipment dealers, extension specialists, and others work with dairy farmers to improve and promote the industry. Approximately 48 percent of Alabama producers belong to the

Free Stalls

Alabama Dairy Herd Improvement Association, which manages a computerized database of production and breeding records that assist with herd and individual cow management. Dairy farmers will continue to develop new and improved business management and other skills as new labor and environmental regulations and safety issues arise.

Free Stalls

Alabama Dairy Herd Improvement Association, which manages a computerized database of production and breeding records that assist with herd and individual cow management. Dairy farmers will continue to develop new and improved business management and other skills as new labor and environmental regulations and safety issues arise.

The Future of Alabama’s Dairy Industry

Since the 1940s, the number of individual dairies and the number of dairy cows in the United States has continued to decline. In addition, remaining dairy operations and herds have become larger and are producing more milk per cow. Alabama has followed suit: Dairy cows peaked in number at 415,000 on more than 100,000 farms in 1944 and dwindled to 44,000 dairy cows on some 330 licensed dairy farms in Alabama by 1987. By 2020, these numbers had decreased to 5,000 dairy cows on 25 dairies, with an average of 200 cows per farm. Despite these decreases, dairy farming still adds more than $25 million to the state’s economy. Handling and processing contribute approximately three times as much money as dairy farm production. Alabama, like most states in the Southeast, is a milk-deficit state, meaning that it produces less than 20 percent of the 300 pounds per person of fluid milk products consumed annually by the state’s residents and essentially none of the additional 300 pounds of other dairy products consumed per capita by Alabamians. Milk is brought into Alabama from states as far away as New Mexico and Wisconsin to supply consumer needs. Alabama’s dairy producers and processors are greatly concerned about this decline because it affects available services, supplies, equipment, and marketing costs and it increases the milk prices paid by consumers. The reasons for the decline are complicated and include increased environmental restrictions, depressed milk prices, urban sprawl and labor availability/cost. In general, the future trend will continue to be toward fewer and larger dairies. Those of moderate size (600 to 1,000 head) will continue to thrive in the state, but given the hurdles mentioned above, it is unlikely that any giant dairies (5,000 to 10,000 head) will be established. Some smaller operations will thrive if they are able to tap into a niche market, such as off-farm sales, effective organic dairying, “grass-fed” milk, or specialty products, such as cheese. With the changes in the state’s demographics, recent interest in establishing goat dairies may occur, but establishment costs for this enterprise can be formidable.